As the global demand for faster internet and more resilient data infrastructure intensifies, fiber optic networks are rapidly expanding across cities, towns, and even remote areas. At the heart of this underground revolution is a powerful yet often overlooked technique—directional drilling. Just like AI is helping businesses in gaining trust, the same goes for directional drilling in fibre optics.

Learn how directional drilling works through an OSP construction contractor, why it’s ideal for fiber optic installation, and why your company should utilize this technique if it’s not doing so already. More information about outside plant construction and related services can be found at Valhalla Industries, which specializes in these solutions.

What Is Directional Drilling?

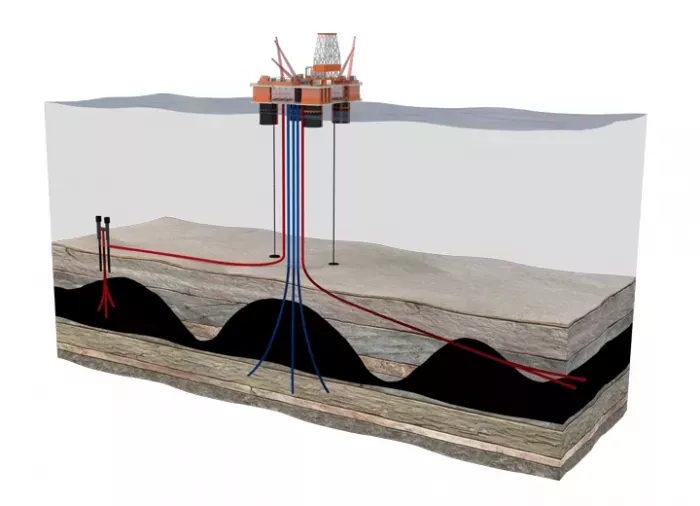

First and foremost, horizontal directional drilling (or HDD) is a trenchless method for installing underground utilities with minimal surface disturbance. It was originally developed for oil and gas, but is now widely used in telecom, energy, and water systems, given its efficacy.

It follows a three-stage process:

- Pilot Bore – A drill head navigates underground toward the destination.

- Pre-reaming (Backreaming) – The borehole is widened to accommodate conduit or cable.

- Pullback – Fiber optic cables are pulled into place through the borehole.

Why Directional Drilling Is Ideal for Fiber Optics

Knowing what directional drilling is and why it’s best for fiber optic installation are two different things. There are five main reasons to consider this technique within your company:

- Precision: Directional drilling allows installers to navigate around existing utilities and hit specific underground targets.

- Efficiency: This technique lowers the time and labor compared to open trenching.

- Minimally invasive: It preserves roads, driveways, landscaping, and sidewalks.

- Environmental benefits: There is less excavation, which means less disruption to ecosystems and less debris to remove.

- Versatility: Directional drilling works in varied terrain, including urban areas, under rivers/roads, and through hard or soft soils.

Applications in Fiber Optic Network Expansion

As fiber optic has begun to grow rapidly across the globe, directional drilling has started to assist with various services in its installation. Fiber to the Home, which is the connections between neighborhoods with minimal driveway or yard disruptions, and urban buildouts going through cities and around sewer, gas, and power infrastructures, is where it’s most prominently helpful.

Challenges and Solutions in Directional Drilling

While directional drilling is a very helpful technique, there are some challenges that can arise with it. Understanding common obstacles and effective solutions is crucial to preventing long-term damage resulting from the project. While there are a slew of challenges that may arise, the most prominent include:

- There are subsurface unknowns in the form of rocks, debris, or undocumented lines

- Directional drilling has accuracy demands as fiber requires gentle curves and protection from stress

- The ground conditions can create issues in clay, sand, or rocky soils

The above issues can often be solved with the assistance of GPS or route planning in advance. By doing so, you can create an underground map of the terrain so that you’re certain what you’re drilling into is safe, non-disruptive, and supportive for fiber optic. When in doubt about the issues you might face, contact professional fiber or outdoor installation firms who can consult on the project.

Regulatory and Safety Considerations

Before you begin a project involving directional drilling, after reading about it here, take heed of the various regulatory and safety considerations that exist. Many municipalities require specific permits for HDD, especially near public utilities or roads.

Before drilling, any of your crews must also use 811 or a private utility locator to mark existing lines. This is imperative to avoid costly line strikes that can result in fees, delays, and injuries. On top of this, there are also environmental compliance issues you need to take into account. Ensure drilling fluids like bentonite are properly contained and disposed of under EPA groundwater guidelines.

Perhaps most important, though, are the worker safety protocols you must take. This spans everything, including rig setup, pressure monitoring, and protective gear standards to meet OSHA regulations. To bolster these protections, ensure the proven is accurate, as-built maps and bore logs help with future maintenance and compliance reviews.

The benefits of directional drilling for fiber optic

Directional drilling is a key enabler of modern, efficient, and scalable fiber optic infrastructure. As demand for high-speed connectivity inevitably grows, trenchless solutions like directional drilling will continue to shape how networks are built. If your business doesn’t have the means to conduct such a project, reach out to professionals to discuss how directional drilling can support your next fiber optic project. By having less mess, more speed, and lasting precision, you can ensure your fiber optic installation goes as smoothly as possible.

Post Comment

Be the first to post comment!