On This Page

- From Sidewalks to Shop Floors

- What Is Cartken and Why Was It Known for Last-Mile Delivery?

- The Inflection Point: Industrial Demand Outpaced Consumer Logistics

- New Lineup: Meet the Hauler, Runner, and the Forklift Bot

- Japan as a Launchpad: Mitsubishi Partnership Powers Scale

- Why the Industrial Pivot Makes Business Sense

- Strategic Lessons from Cartken’s Shift

- What’s Next for Cartken?

- Final Word: From College Lunches to Industrial Payloads

From Sidewalks to Shop Floors

In a move that signals a broader trend in robotics, Cartken—a startup once known for its compact autonomous delivery robots zipping across campuses and city streets—has shifted gears. The company is now focusing its engineering talent and AI stack on the industrial sector, targeting warehouse logistics, factory automation, and production workflows.

According to TechCrunch, this strategic pivot was not merely opportunistic. It’s a calculated response to stronger demand signals, faster sales cycles, and higher ROI offered by enterprise clients—especially in manufacturing, logistics, and supply chain ecosystems.

What Is Cartken and Why Was It Known for Last-Mile Delivery?

Cartken originally made headlines with its cooler-sized, six-wheeled delivery bots called Courier. These robots were deployed across U.S. college campuses and even licensed in Japan through a partnership with Mitsubishi. Designed to transport food and small packages, Couriers relied on a combination of computer vision, sidewalk-trained AI, and LIDAR-free autonomy to navigate complex pedestrian environments.

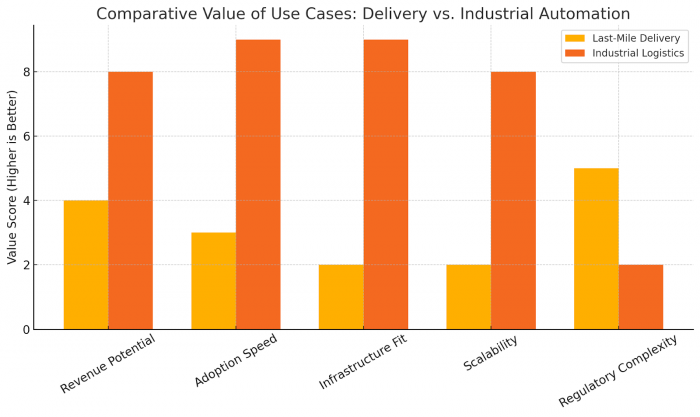

While the robots worked well in urban settings, the last-mile delivery business posed limitations:

- Low margins and long B2C adoption cycles

- Intense regulatory overhead

- Seasonal demand fluctuations

- Heavy competition from gig economy models

The Inflection Point: Industrial Demand Outpaced Consumer Logistics

In 2023, a key moment came when ZF Lifetec, a German automotive supplier, began using Cartken’s Courier bots to move product samples around its campus. What started as a test became one of ZF’s highest-utilized systems. According to Cartken co-founder and CEO Christian Bersch, that deployment proved something critical: Cartken’s robots could offer immediate and measurable value in industrial operations.

This success catalyzed a bigger idea—what if Cartken applied its same autonomy stack to heavier-duty tasks?

New Lineup: Meet the Hauler, Runner, and the Forklift Bot

To address industrial applications, Cartken has released a modular fleet:

| Robot | Description | Payload Capacity |

| Courier | Original sidewalk bot for food & parcels | Up to 44 lbs |

| Runner | Indoor campus robot for light goods | Lightweight |

| Hauler | Warehouse logistics robot | Up to 660 lbs |

| Forklift Bot (Upcoming) | Autonomous pallet handler | In development |

The core autonomy system remains the same—vision-based, sensor-light, trained on real-world pedestrian environments.

But the outer hardware now varies to match industrial use cases such as:

- Line-side delivery in factories

- Automated sample movement in R&D labs

- Cross-department payload transfer in pharma campuses

- Campus-wide logistics in large enterprises

Japan as a Launchpad: Mitsubishi Partnership Powers Scale

Cartken’s deep partnership with Mitsubishi Electric Mobility (Melco) helped the startup gain regulatory clearance to operate in Japan. After 4 years of joint development, Melco is now preparing to deploy nearly 100 Hauler bots in industrial settings across Japan. This marks Cartken’s biggest enterprise deployment to date.

Unlike in last-mile delivery, the Japanese rollout has been smooth, thanks to industrial customers’ clear infrastructure, repeatable workflows, and long-term automation goals.

Why the Industrial Pivot Makes Business Sense

Bersch told TechCrunch that while food delivery still exists in Cartken’s portfolio, it is no longer the growth focus. Instead, industrial clients are:

- Faster to adopt robots

- Willing to pay more for high-impact automation

- Easier to scale within predefined environments

- Looking for predictable uptime, not promotional hype

Cartken's robots now work in facilities where even minor efficiency gains translate to thousands in daily savings—whether it’s moving prototype parts in an EV factory or handling sterile material in a pharmaceutical plant.

Strategic Lessons from Cartken’s Shift

1. Start with Consumer Data, Apply to Enterprise

Years of sidewalk and campus training gave Cartken a rich dataset to fine-tune its vision AI. That same tech now gives it a competitive edge in navigating dynamic indoor environments.

2. Modular Hardware, Unified AI Core

Instead of building robots from scratch for each industry, Cartken is using a modular AI stack and adapting hardware to suit different payloads and terrains.

3. Pivot When Market Fit Is Clear

Rather than waiting for last-mile delivery to “catch up,” Cartken aligned with industries already demanding automation today—not hypothetically in 5 years.

What’s Next for Cartken?

With over $20 million in funding raised so far, Cartken is scaling its manufacturing and enterprise deployments. The company plans to deepen its footprint in Japan, expand into North American factories, and continue R&D on its robotic forklift system.

While it hasn’t entirely exited the food delivery market, Cartken is treating it more as a sandbox for real-world navigation testing rather than a revenue engine.

Final Word: From College Lunches to Industrial Payloads

Cartken’s pivot is a textbook example of responsive product-market alignment. As the robotics landscape matures, startups like Cartken are realizing that industrial environments offer something the consumer world often lacks: clarity, budgets, and automation-ready workflows.

In the coming years, we may see more consumer robotics companies following Cartken’s lead—retraining their AI, repackaging their hardware, and redirecting their mission toward the factories, warehouses, and research campuses powering the global economy.

Post Comment

Be the first to post comment!